COMPLETE HW

AND SW SOLUTIONS

CUSTOM

PROGRAMMING

CONSULTING

AND TRAININGS

- do you lack the input, output or inter-operational inspection of the product in the production line?

- do you need fast and automated check of quantity, position, shape, dimension or presence of elements of your products?

-

do you have an older or outdated testing, metrological or manufacturing machine still working,

but lacking powerful controlling, graphical or evaluation unit?

Let our systems meet your visions

Our customers can benefit from the advantages of hardware and software,

which was designed with their cooperation; systems fulfill required functions for

100% and their inputs and outputs are fully compatible with customer's needs.

How we work?

Powerful and intuitive software

Our software is powerful tool to make your work quicker and more efficient. It can provide everything, from controlling and evaluation process to communication with peripherals - whether it is a printer or an automated production line. Software adapts to logged user to provide just the right and required information. In short, our software solutions are intuitive and user-friendly - our trainings usually take no more than one day.

Individual approach

We benefit from our long-term experience in measuring, inspection and testing. Thanks to this we know that every customer and every task is unique and requires an individual approach.

High quality components

We do not sell universal platforms with lot of unnecessary functions. We create solutions based on your needs and requirements using proven and cutting edge components from leading suppliers of measuring and sensor technology.

References

-

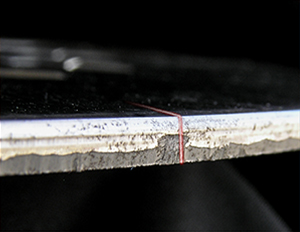

MACHINE FOR INSPECTION

OF SHEARED METAL SHEETS

During shearing process of special sheet metal parts, the tearing of the material occurs at their edges, which can shorten their lifetime. Thus, inspection is necessary. unIQsys designed and built a complete automated measuring system for evaluation so-called "ratio of the clean shear" at the edge. Using the laser scanner, the entire perimeter of the part is digitized and the areas with the worst pressing result are localized. The device is located directly in production and covers the entire production portfolio, which consists of more than 300 types of parts of different diameters, shapes and thicknesses.

-

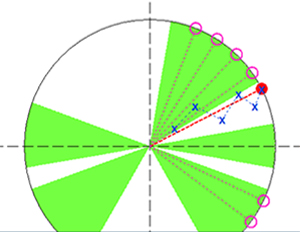

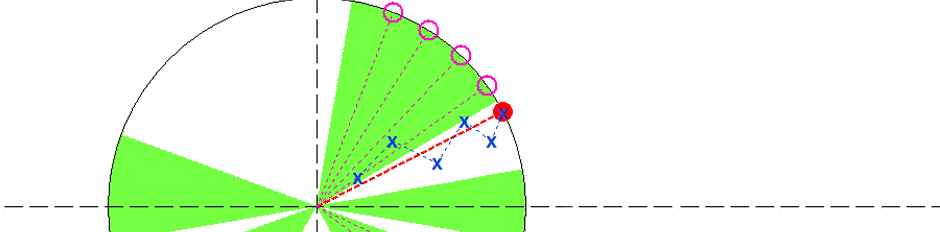

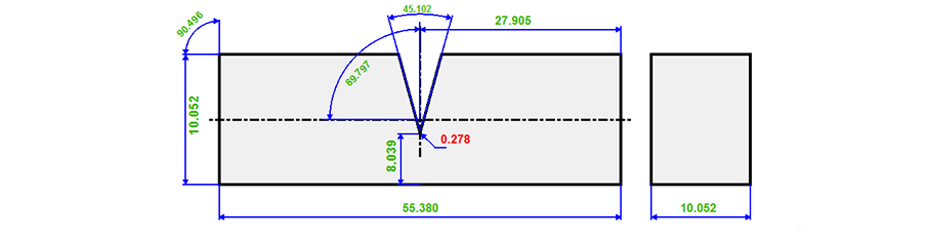

ALGORITHM FOR AUTOMATED

BALANCING MACHINESEspecially in automotive industry, a large number of rotating parts are additionally corrected for any dynamic imbalance. Corrections are made by drilling, riveting, milling, etc. unIQsys has created a software module (mathematical algorithm library) for the needs of the developer, which calculates optimal balancing corrections based on input parameters (maximum drilling depth, weight of the rivets used, maximum number of weights, etc.).

-

METROLOGICAL SOFTWARE

FOR OPTICAL DIMENSION

INSPECTIONWith modern high-res industrial cameras, non-contact measurements can be made with micrometer accuracy. However, the processing of the acquired data is extensive. Thanks to years of experience, unIQsys engineers have developed a complete evaluation software controlled by the operator through a user-friendly touch interface and provides all the necessary tasks from measuring to the output measuring report.

Contact

Years of experience taught us, that understanding your needs and knowing details of your request is one of the most important steps within project.

Therefore we prefer personal meeting. Please do not hesitate to contact us and arrange meeting directly at your branch office.

Operation scope of our company is entire Central Europe.